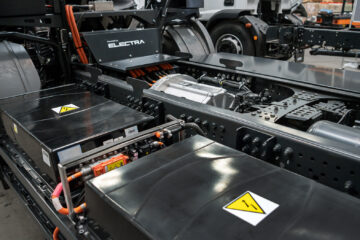

Driving force – Batteries from world-class manufacturers for outstanding performance – Electra’s modular approach, the latest software and hardware, and ease of maintenance for internal and external parties make our batteries achieve more cycles, longer life, better long-term performance, and higher economic benefits.

Any place – any time. Change or service any component in record time – Electra has looked at the challenges and designed a platform to suit the demands of a vehicle being operated anywhere globally. Designing the layout of the sub-components in an industry-first packaging design means any of the powertrain components can be serviced or replaced in under 15 mins.

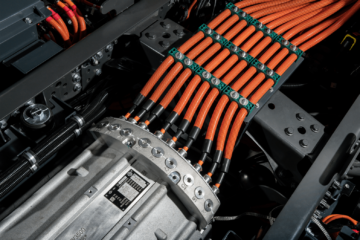

Tailored motor & ePTO solutions – Electra match each driveline motor to each chassis platform we create. A calibrated setup is essential for excellent performance. Electra’s powertrain far surpasses internal combustion engine equivalents. Vehicle bodies often have hydraulic power demands for operation. For this reason, Electra match a suitable motor and pump combination to operate from the vehicle’s HV batteries. This configuration means that no separate power source is required for the body. Electra work closely with OEMs and battery manufacturers to ensure that all applications operate smoothly and silently.

Electra’s vehicles come with a fully integrated telematics system – providing full operational transparency – Electra’s in-house telemetry platform is the most valuable tool for operating our vehicles. Alerts warn of instances such as a vehicle not charging, inefficient driver behaviour, energy usage and regen use. Preventative maintenance regimes based on the data mitigate downtime. The system creates reports at any time for fleet/vehicle usage and comparisons to diesel equivalents. Electra’s operators use transparent fleet data for reports to board members to prove the energy savings generated.